Contact us 24hrs a day; OTISLINE (800) 233-6847 (EN) OTISLINE (800) 238-6847 (FR) OTISLINE (800) 872-6847 (ES) Local and regional contact information. Our elevators are commercial-grade quality at a more affordable cost. We use cabinet-grade seven-ply plywood and solid hardwood trim on all of our elevator cabs. Quality and safety are our priorities for our elevators. While you may find a lower price point elsewhere, you will likely get what you pay for. A top-quality home elevator is worth. Manufacturing and Management: Mr. Mukesh Patel: Phone:- (+91) Email:- mukesh@foxelevator.co Product control and Documentation: Mr. Nishit Patel: Phone.

Nationwide Lifts has the most complete and innovative product line in the industry. We strive to develop new products and partnerships, giving homes and businesses exactly what they need. With our network of offices and affiliates, Nationwide Lifts is capable of fulfilling your elevator needs anywhere in North America!

When it comes to residential elevator systems, hydraulic drives are a popular choice for homeowners looking for quality, safety, and the ‘quietest’ ride.

Hydraulic home elevator systems utilize a ram or piston to raise and lower the car by filling or releasing fluid into an airtight cylinder. With more standard features and custom options than any other elevator on the market today, Symmetry’s Hydraulic Drive Residential Elevator system is the industry leader.

Unique in the market, no other company offers emergency battery-operated lowering, COP and hall stations digital position indicators, custom wood sills and energy-efficient LED lighting as standard features.

This drive system accommodates up to six stops, 50’0″ of travel and is equipped to hold up to 1,000 pounds.

Find a local Symmetry hydraulic elevator dealer to discuss your needs!

- Travel: Maximum of 50’0″ (minimum 12” between stops)

- Speed: 40 feet per minute

- Rated Capacity: 1,000 pounds

- Pit depth: 6” minimum (8” preferred)

- Stops: Two

- Opening: Single

- Overhead: Minimum of 7’10″ (94 inches) with a 7’0″ interior car height

- Warranty: Three-year limited parts

- Modular 6-1/4 pound T-rail structure

- Car frame assembly

- 208/230 VAC, 60 Hz, 30 amp, single-phase power supply for motor controller

- 120 VAC, 60 Hz, 15 amp, single-phase power supply

- Code-compliant electrical disconnects included*

- Two 3/8″ 7×19 galvanized aircraft cables (14,400 lbs. breaking strength) with wedge rope shackles

- 80 mm diameter piston/102 mm diameter cylinder including 3/4 inch reducer bushing

- 3 HP submersed motor with 2-speed valve assembly

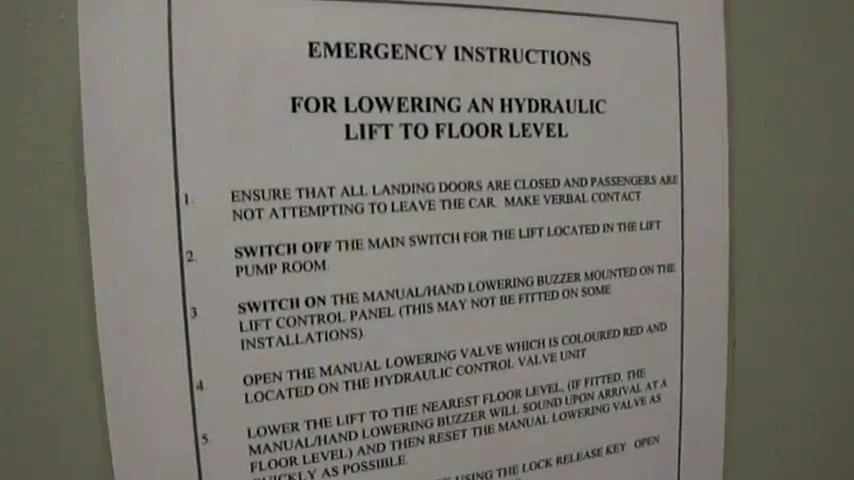

- Manual down valve for emergency lowering

- Slack rope safety device

- Line rupture valve

- Motor controller supply disconnects (located in controller)

- Car light supply disconnects (located in controller)

- Pit stop switch

- Car-top stop switch

- In-car emergency stop switch and alarm

- Safety switch for car gates/doors

- Battery backup emergency car lights and alarm

- Electro-mechanical hoistway door locking devices (doors by others)

- Enhanced gate/bypass monitor

- Programmable Logic Controller (PLC)

- Non-selective collective automatic operation

- S.M.A.R.T. System (Self-Monitoring Alert Response Technology)*

- Car Operating Panel (COP) with LED floor position indicator §

- Hall stations with call button and LED floor position indicator §

- Recessed phone box (phone jack included) §

- Automatic car lighting

- Single floor designated car homing

- Uninterruptible Power Supply (UPS) for car lowering and automatic car gate/door operation (if provided) in the event of power failure*

- Car size up to 15 square feet

- 7’0” interior car height

- Birch, Oak, or Maple flat veneer interior walls with flat ceiling*

- Matching wood handrail

- Matching wood car sill

- Unfinished plywood floor with sill set for 3/4” (flooring by others)

- 2 energy-saving recessed LED lights with Black trim rings*

- Light Oak, Birch or White 7’0” laminate accordion door

- Up to six stops

- Single automatic push button operation

- Custom car size up to 18 square feet**

- Custom car heights

- Shaker or Recessed panel car with flat ceiling

- Shaker, Recessed or Raised panel car with matching ceiling

- Four recessed LED lights with Black, Polished Brass, Brushed Nickel or Bronze trim rings*

- Factory-finished car

- Fixtures including COPs, hall stations, phone boxes and handrails available in:

- Polished or Blackened Stainless Steel

- Brushed, Polished or Oil-Rubbed Solid Brass

- Powder-Coated Black or Vintage Bronze

- COP with integrated keypad phone

- Custom wood interiors

- Custom factory finish, Distressed*

- “Green” material alternatives and finishes for car interiors*

- 3/4 inch finished or unfinished installed hardwood car flooring

- Factory flooring insert for 1/4 inch flooring by others

- Buffer springs (requires minimum of 8-1/4 inch pit depth)

- Key switch for COP and/or hall stations

- Rated Capacity: 750 and 950 lbs.

- Light curtain monitoring the car entrance

- ‡Symmetry Safety 3-Panel car door*

- Two or three speed car door or car and landing doors

- Wrap around car door ‡

- Dark Oak, Chalk, Antique White, Cherry, Walnut or Black laminate accordion door

- Hardwood veneer accordion door

- Clear or Smoked acrylic panel accordion door

- Automatic car gate/door operator (not available on Enterprise collapsible gate)

* This symbol denotes Symmetry exclusive features

** May require local code authority approval

‡ Availability depends on code year

§ Standard finish is Brushed Stainless Steel, but multiple finishes available

Whether you’re looking to install a new system or are curious about how your existing machinery works, here’s everything you need to know about hydraulic elevators.

What is a Hydraulic Elevator?

There are two main types of elevator systems: traction and hydraulic.

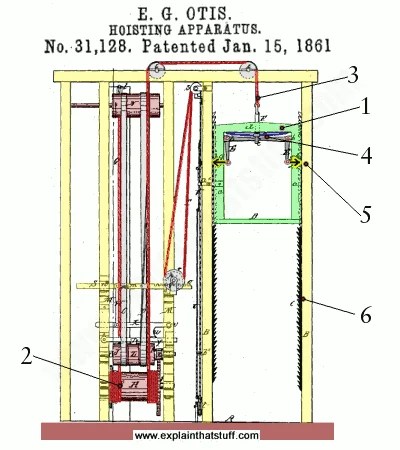

Traction elevators utilize steel ropes or belts on a pulley system. Hydraulic elevators are powered by hydraulic jack, which are fluid-driven pistons that travel inside of a cylinder.

How Do Hydraulic Elevators Work?

Unlike traction elevators, hydraulic systems don’t use overhead hoisting machinery. Instead, these elevators use the compression of fluids to generate movement.

The elevator cab is lifted by an electric motor that pumps oil into the cylinder to move the piston. Hydraulic elevators also incorporate electrical valves to control the release of oil for a gentle ride.

The fluid needed to power a hydraulic elevator must be oil-based. Vegetable oil or biodegradable oil can be used as environmentally friendly options.

What Types of Buildings Use Hydraulic Elevators?

You can find a hydraulic elevator in almost any type of building. However, there are two factors that limit the heights they can travel.

Hydraulic elevators require a substantial amount of energy to raise the cab, which is why they’re not usually found in high-rise buildings. These systems also operate at speeds of 150 ft./min. or less, making them slower than other types of elevators.

Because of these factors, hydraulic elevators are only intended for buildings that are up to seven stories.

What Are the Different Types of Hydraulic Elevators?

Not all hydraulic elevators are created equal! There are several variations that can make each system unique.

Holed Hydraulic

With this type of elevator, hydraulic cylinders extend into the ground and are placed inside of a drilled hole. The car of the elevator is mounted on a piston that travels inside of the cylinder, allowing up to 60’ of travel.

Hydraulic Otis Elevator Phone Line Manual Download

Holeless Hydraulic

Since a drilled hole isn’t necessary, existing buildings or areas where drilling isn’t an option can benefit from a holeless hydraulic elevator. However, these models aren’t suited for more than 40’ of travel.

Roped Hydraulic

Roped hydraulic elevators use cables and a piston attached to a sheave to extend the rise of a holeless hydraulic elevator. Since a rope is holding up the elevator cab, a governor is required. These models are intended for 60’ of travel.

Machine Room-Less (MRL) Hydraulic

In machine room-less elevators, the hydraulic lift mechanisms are located in the hoistway instead of a separate machine room. This maximizes the available space in a building.

What Are the Benefits of Hydraulic Elevators?

For many types of buildings, hydraulic elevators offer the following advantages:

- Quicker to install than other elevator types

- Less expensive to install and maintainIdeal for transporting heavy loads

- Occupy less space in a building

- Option to have machine room-less configuration

What Are the Disadvantages of Hydraulic Elevators?

Even with the benefits, there are still a few factors that might not make hydraulic systems the right choice for certain applications:

- Only intended for low and mid-rise buildings

- Can only travel up to 150 ft./min.

- More power requirements than traction elevators

- May be a bit noisier than other systems

Examples of Hydraulic Elevators

thyssenkrupp endura

Offering a smooth and quiet ride, the thyssenkrupp endura hydraulic system is one of the most notable elevators of its kind. This hydraulic elevator is available in holed, and holeless models and can be customized to your building’s specifications.

Elevator Emergency Phone

Do You Need Help with a Hydraulic Elevator?

Hydraulic Otis Elevator Phone Line Manual Software

With 65+ years of experience, Stanley Elevator can modernize or service your existing hydraulic system or help you install a new hydraulic elevator. Contact us here and a member of our team will be glad to help!